Plastic Injection Molding service

The process can produce precise complex plastic products action of a gram to more than a hundred

kilograms, in virtually any plastic material. The process starts with feeding small plastic beads into a

heated screw and barrel system that melts the plastic into a high–viscosity liquid. The screw then

forces the molten plastic into a closed mold that provides the shape, cooling, and solidification, and

finally ejects the part. China Injection molding is fast and can be economical. But because every part

needs its own costly injection molding tool, the process is economically viable only for mass production,

usually more than 10,000 parts.

China Injection molding tools take weeks to build. Often, design mistakes become apparent, requiring

time–consuming mold corrections. Multiple iterations may go from the producer to the tool builder until the final

part design and quality are achieved, increasing costs and product time to market.

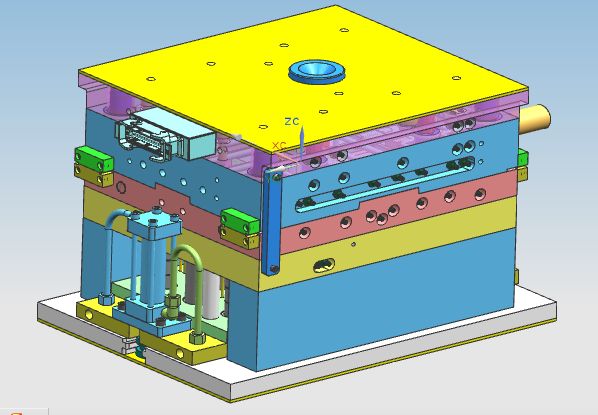

Plastic Injection molding is a method of producing parts with a heat-melt able plastics material.

This is done by the use of a plastic injection molding machine. The shape which is produced is controlled by

what is called a “mold china” The plastic injection molding machine has two basic parts; the injection unit,

which melts the plastic and then injects or moves it into the mold, and the clamping unit, which holds the

mold. The unit clamps the mold in a closed position during injection, opens the mold after cooling, and ejects the finished part.

Materials can be used in a process called china injection molding

These are thermoplastics such as polystyrene, nylon, polypropylene, and polythene – this means when

they are heated and then pressured in a mould they can be formed into different shapes. China injection

molding unit seen opposite has been made in one piece using this process An animation of an injection

moulding process is shown below. Injection moldings count for a significant proportion of all plastics

products from micro parts to large components such as bumpers and wheelie bins. Virtually all sectors

of manufacturing use injection molded parts – the flexibility in size and shape possible through the use

of this process have consistently extended the boundaries of design in plastics and enabled the significant

replacement of traditional materials thanks to light-weighting and design freedom. The table below shows

the type of products that can be injection moulded but is by no means comprehensive.

Plastic Injection Molding service industry include following

1,Assemblies

2,Consumer Products

3,Containers

4,Medical / Dental Disposable

5,Electrical / Computer Parts

6,Food & Beverage

7,Insertion Molding

8,Living Hinge

List products that have been manufactured through injection moulding. Reference article for china injection molding companies