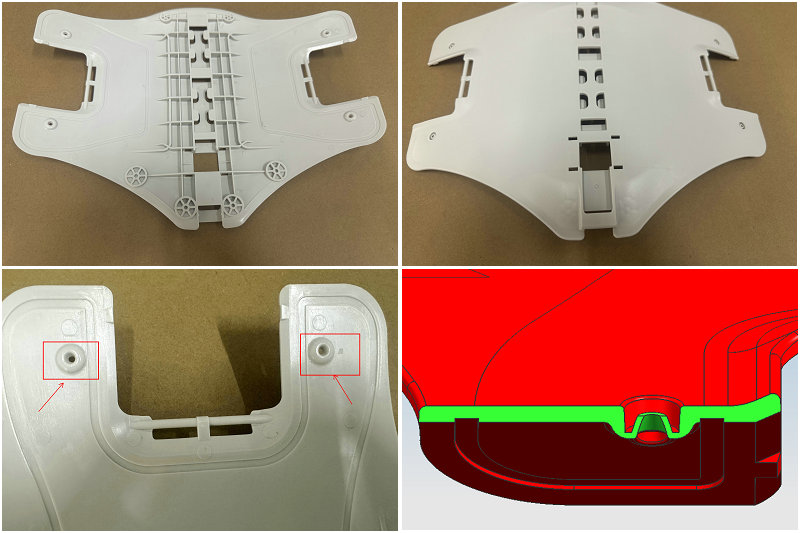

We produce medical stents for our international clients. However, due to the use of different tools, there have been deviations in the dimensions of the stents, which do not meet the required specifications. As they are current 2.54 mm in diameter and client need to be 2.44 mm in diamete.But it is not the wrong size, but the deviation caused by different measuring tools. After many measurements, it is proved that this position can not be measured with calipers, because the edge of the hole is sharp, and the strength is slightly larger, you can measure the size of the hole, and the best way is to measure it with a gaugeical Injection Molding

It is crucial to understand that these are special products and therefore require special testing methods to ensure their quality and compliance with international standards.

The use of different tools has resulted in variations in the dimensions of the medical stents. This deviation from the required specifications is a matter of concern as it can impact the effectiveness and safety of the stents when used in medical procedures. It is imperative that we address this issue promptly and implement measures to rectify the situation.

In order to ensure that the medical stents meet the necessary standards, it is essential to employ special testing methods that are specifically tailored to the unique characteristics of these products. These testing methods should take into consideration the material composition, structural design, and intended application of the stents. By utilizing specialized testing techniques, we can accurately assess the dimensional accuracy, mechanical properties, and biocompatibility of the stents.

Additionally, we must prioritize the implementation of stringent quality control measures throughout the production process to prevent any deviations in the dimensions of the medical stents. This may involve standardizing the use of specific tools, conducting regular inspections, and implementing corrective actions to address any discrepancies.

By addressing the issue of dimension discrepancies in our medical stents and implementing specialized testing methods, we can uphold our commitment to delivering high-quality products that meet the stringent requirements of our international clients. This proactive approach will not only safeguard the reputation of our company but also contribute to advancing healthcare outcomes globally.

In conclusion, the production of medical stents for international clients requires meticulous attention to detail and adherence to specialized testing methods. By acknowledging the impact of tool variations on dimensional accuracy and taking proactive measures to address this issue, we can ensure that our medical stents meet international quality standards and deliver optimal performance in clinical applications.