The Need for Temperature Control in Plastic Injection Molding

Temperature control prevents quality issues such as shrinkage, warping, and stresses from developing in the injection-molding processes.

What is the mold temperature in injection molding?

Injection molding is a widely used manufacturing process that involves the creation of products by injecting molten material into a mold. This process is used to create a variety of products, including plastic parts, toys, and medical devices. One of the most critical factors for successful injection molding is temperature control.

Temperature control is essential in injection molding because it affects the quality and consistency of the final product. The temperature of the molten material, the mold, and the cooling system must be carefully controlled to ensure that the product is produced correctly.

- The temperature of the cooling fluid.

- The rate of mold cooling.

- The quality of the final product, keeping in mind that the speed of production is proportional to profitability.

The temperature of the molten material must be carefully monitored and controlled to ensure that it is at the correct temperature for injection into the mold. If the temperature is too high, the material may degrade, resulting in poor product quality. If the temperature is too low, the material may not flow properly, resulting in incomplete parts.

The mold temperature is also critical in injection molding. If the mold temperature is too low, the material may not fill the mold completely, resulting in incomplete parts. If the mold temperature is too high, the material may cool too quickly, resulting in warping or other defects.

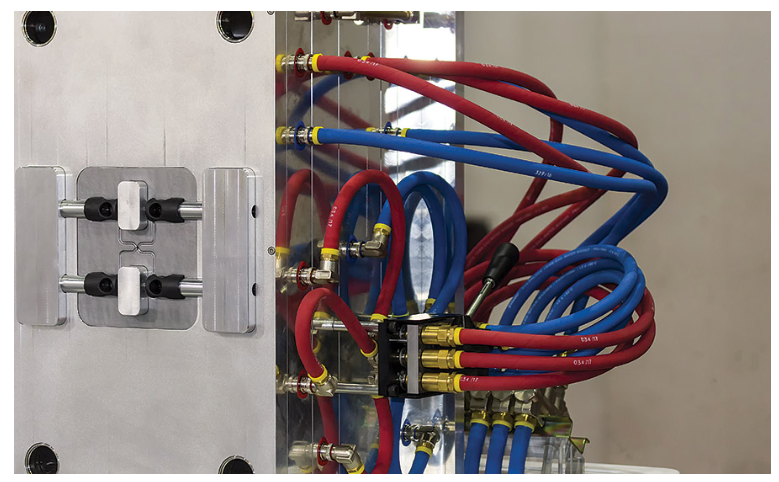

The cooling system is also essential in injection molding. The cooling system must be designed to cool the product quickly and evenly to prevent warping or other defects. If the cooling system is not designed correctly, it may result in uneven cooling, resulting in warped or distorted parts.

Temperature control is critical in injection molding because it affects the quality and consistency of the final product. If the temperature is not controlled correctly, it may result in poor product quality, incomplete parts, warping, or other defects. To ensure that temperature control is maintained throughout the injection molding process, it is essential to use advanced temperature control systems that can monitor and adjust temperatures in real-time.

In conclusion, temperature control is essential in injection molding because it affects the quality and consistency of the final product. To ensure that temperature control is maintained throughout the injection molding process, it is essential to use advanced temperature control systems that can monitor and adjust temperatures in real-time. By doing so, manufacturers can produce high-quality products consistently and efficiently.

Reference video for China Injection Molded Plastics at