Precision injection mold characteristics

Plastic mold production with the general production of mechanical products in common, while its particularity. Compared with the general machinery manufacturing, mold manufacturing is usually more difficult, especially for precision molds. As special process equipment, Precision injection mold production and process mainly in the following aspects of the characteristics.

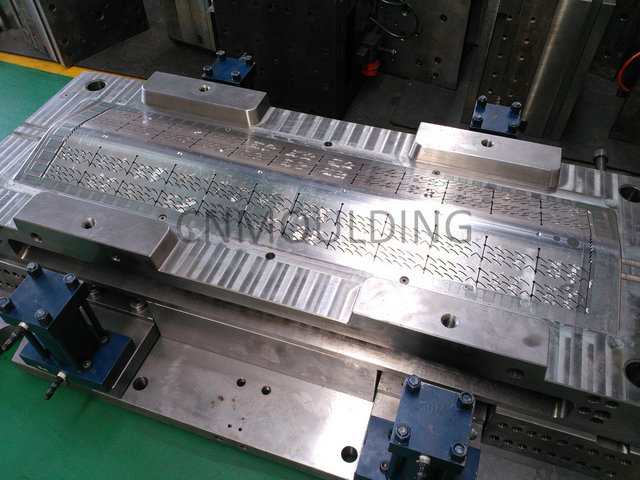

1. Precision mold manufacturing quality requirements,

Not only requires high precision machining, but also a good quality processing surface. In general, the manufacturing parts of the mold part of the manufacturing tolerances should be controlled within ± 0.011mm, and some even require in the micron range, the mold surface defects after processing requirements are very strict, and the working part of the surface roughness requirements Ra <0.8 Um.

2. Complex shape

The working parts of precision molds are generally two-dimensional or three-dimensional complex surface (especially cavity mold),

rather than the general machining of simple geometric profiles.

3. Process complex

Mold production for the single, multi-species production of each mold can only produce a specific

shape, size, and accuracy of the pieces. In the manufacturing process as far as possible the use of general machine tools, general tools, and

instruments, as much as possible to reduce the number of special tools used. In the manufacturing process requires a relatively centralized

process to ensure that the mold processing quality and accuracy, simplify management and reduce the process turnaround time.

4. High hardness of the material

Plastic mold is actually a mechanical processing tool, the hardness requirements are higher, are generally quenched alloy tool steel or carbide

and other materials, if the traditional mechanical processing methods are often more difficult, so the mold processing The method is different from the general machining.

5. Short production cycle

As the product upgrading and market, competition is becoming increasingly fierce, requiring mold production cycle is getting shorter

and shorter. Mold production management, design and process work should be adapted to this requirement, to improve the mold design,

manufacture, and standardization, in order to shorten the manufacturing cycle.

6. Complete production

When a part of the need for multiple mold processing, the former mold made of the product in the

back of the blank mold, mold parts of the implicated in each other, only the final product qualified,

some of the molds are considered qualified. This feature must be taken into account in the production and planning of molds.