As a professional plastic injection molding company in china. Cn-moulding is able to provide different plastic injection molded parts. Such as insert molding, double-color molding, multi-cavity plastic molding, and hot runner plastic moulding with Polyacetal/Acetal material.

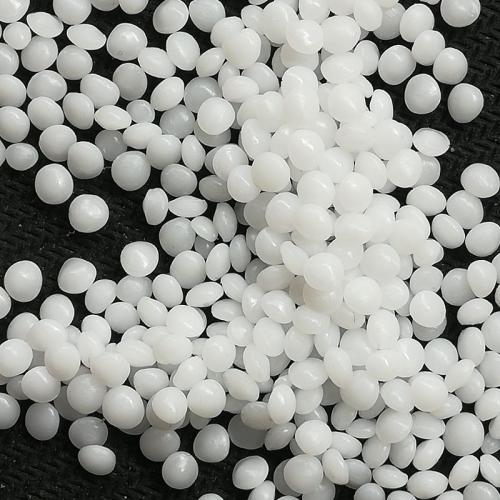

Characteristics of POM-Plastic Material

POM-plastic material is a highly crystalline thermoplastic material that has excellent mechanical properties. It is resistant to wear, abrasion, and fatigue, making it suitable for use in applications that require high strength and durability. POM-plastic material has a low coefficient of friction, which makes it an excellent choice for applications that require low friction and smooth movement. It is also resistant to chemicals, solvents, and oils, making it suitable for use in harsh environments.

Applications of POM-Plastic Material

POM-plastic material is widely used in different industries due to its exceptional properties. It is commonly used in the automotive industry to manufacture gears, bearings, and other components that require high strength and durability. POM-plastic material is also used in the medical industry to manufacture surgical instruments, drug delivery systems, and other medical devices. It is also used in the consumer goods industry to manufacture zippers, buttons, and other components.

Advantages of POM-Plastic Material

POM-plastic material offers several advantages over other materials. It has excellent mechanical properties, which make it suitable for use in applications that require high strength and durability. It is also resistant to wear, abrasion, and fatigue, which means that it can withstand harsh environments. POM-plastic material has a low coefficient of friction, which makes it an excellent choice for applications that require low friction and smooth movement. It is also resistant to chemicals, solvents, and oils, which means that it can be used in harsh environments.

Disadvantages of POM-Plastic Material

POM-plastic material has some disadvantages that should be considered before using it in specific applications. It has poor UV resistance, which means that it can degrade when exposed to sunlight. It is also sensitive to moisture, which can cause it to degrade over time. POM-plastic material is also prone to stress cracking, which can occur when it is exposed to certain chemicals.

Process conditions for injection molding:

1, Drying: the moisture absorption of the resin itself is very small, so it is not necessary to dry. But if the water content during molding is greater than 0.1%. It needs to be dried, which is also conducive to avoiding the phenomenon of mold scale. But for some filling grades. Such as carbon fiber filling, and conductive grades. It must be dried, in drying conditions of 80-90℃, 3~4 hours.

2, Recycling: recycled materials can be used. Even if 100% of recycled materials are used 10 times. Their physical properties basically will not change, but the color will change. In principle are 25-30% recycled materials and 75-70% new materials mixed-use.

3, Thermal stability: stay at the temperature of 210℃ for 60 minutes before molding. The tensile strength of the molded product hardly changes. It has good thermal stability.

4, Injection machine: general injection molding, projection area x40-60mpa of mold-closing force > moulds.

5, Cylinder capacity: the product weight is generally 40-80% of the cylinder capacity.

6, Nozzle and latching system: open nozzle is available, but to prevent salivation. It is best to choose a latching nozzle.

7,Screw: use standard screw, compression ratio 2.8-3.0:1, length-diameter ratio: 18-22:1.

8, Cylinder temperature: the melting point of the resin is about 165℃.The optimal temperature for actual molding is 190-210℃, preferably 200-210℃.

Conclusion

POM-plastic material is a highly crystalline thermoplastic material that has excellent mechanical properties. It is resistant to wear, abrasion, and fatigue, making it suitable for use in applications that require high strength and durability. POM-plastic material has a low coefficient of friction, which makes it an excellent choice for applications that require low friction and smooth movement. It is also resistant to chemicals, solvents, and oils, making it suitable for use in harsh environments. However, POM-plastic material has some disadvantages that should be considered before using it in specific applications. Overall, POM-plastic material is an excellent choice for applications that require high strength, durability, and low friction.