Injection Mold tryout

In China, After the injection mold has to go through several test modes, most small and medium die to use.

1-3 times tryout, medium-sized injection mold takes 3 to 5 times, the structure particularly complex mold tryout times will be more likely.

How many times are mold and equipment and operating processes employed Qualities related, and injection mold

design, production quality, and other factors are closely related. Meanwhile, to some extent reflects a mold factory technical level.

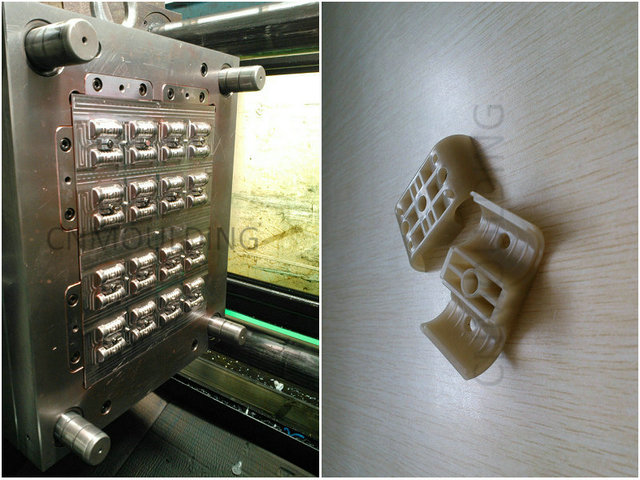

Most can fully reflect the level of the injection mold in the last tryout sample provided. The sample is usually sent to the ordering side, to check the results as an important basis for a mold inspection time. The basic sample size correct or not may reflect the manufacture of precision molds. Therefore, in the acceptance process, the first products are to be accepted.

After processing is complete 16 hours post-acceptance, at least in parts molded plastic parts or requested. Acceptance of the standard ambient temperature 23 ± 2 ℃, relative humidity 50 ± 6%, dew point temperature 21 ℃. Atmospheric pressure 890 ~ 1060hPa, air velocity ≤1m / s. If the actual environment is not standard. It can be carried out under the conditions of both parties. Or the measured value corresponding to the length of the correction coefficient of expansion.

First, product acceptance

1. The basic dimensions of test products

Obtain a sample, the first to observe its overall shape is correct. Whether the basic shape meets the product design. Then the basic dimensions of products for testing.

2. Products with the size of the test

The size of the article refers to the interaction between products products products and related components, or between, including the local relative position with the size and overall dimensions.

3. Test assembly inspection

When the basic size, dimensions, with the size of the inspection, deemed essential meet the design requirements.

You can try assembly inspection. This is a very important means of checking products, which can tie verify dimensions of space surface for verification.

4. The product appearance quality inspection

When the pre-meet the requirements. The need for apparent quality parts to conduct a comprehensive inspection. Then the apparent mass refers to the absence of a common defect condition. The apparent quality meets the requirements.

5. Balancing and static balance test

For the high-speed operation of the components to be dynamic and static balance test. The strength of the high demand for parts. To conduct impact tests, strength, high-temperature testing.

Second, the injection mold inspection process in china

After the workpiece through a comprehensive inspection, acceptance want to die, mentioned earlier, can provide a complete sample of the mold. The whole structure can be regarded as reasonable. However, other parts of the mold

still recognize factors really check processing precision parts mold structure, insert mode, heat treatment methods. And other aspects directly affect the life of the injection mold.

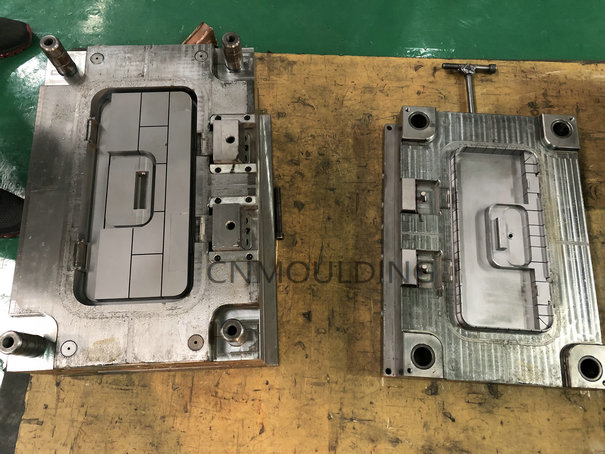

1. The injection mold appearance quality

A plastic injection mold before, the first observation of its template machining level, templates straight. The following are grinding forming. Dimensions tidy edges chamfered (2 ~ 5) mmX45 °, and give people

Leave a good impression, even reminiscent of the inside of the mold machining quality must be excellent. If the outer surface of the rough, choppy template, although does not affect the intrinsic quality. But it makes it hard to imagine such a plastic mold capable of producing high-quality products.

2. The main part size injection mold inspection

After the acceptance of plastic parts, cavity size is correct or not basically been confirmed, mold other aspects of dimensional tolerances required further examination.

3. Status of main structural parts

Ensure the normal operation of the injection mold structure moving parts, injection mold inserts, inserts slide and motion wearing parts, and the like.

4. Plastic Injection Mold Materials Handling in China

In the injection mold design, the user can make special requests to mold materials, heat treatment mold standard parts can be carried out in accordance with national standards.

5. wearing parts and spare parts

Each mold has its wearing parts, and thus at the china mold factory, it should be equipped with spare parts. Some non-standard items require the simultaneous production of two mold factories to prepare for plant replacement.