Injection mold guide

Part: Part refers to the customer’s drawings or samples of customized plastic parts.

Tool: Creation tools refers to the injection mould of the plastic spare parts forming process

Shrinkage: shrinkage rate refers to how many plastic materials after cooling.This part of the contract before they are added to the mold design. Each one has its own shrinking from plastic materials.11 samples per inch.060 per inch.Although most somewhere in between.004.021.It is very important in selecting a range of plastic material, you might want to test building injection molds. For example, if you want to use is polycarbonate.006 per inch and nylon.015 per inch you may want to set up the mould.010 or leaving critical size safe raw materials until the last one is selected.

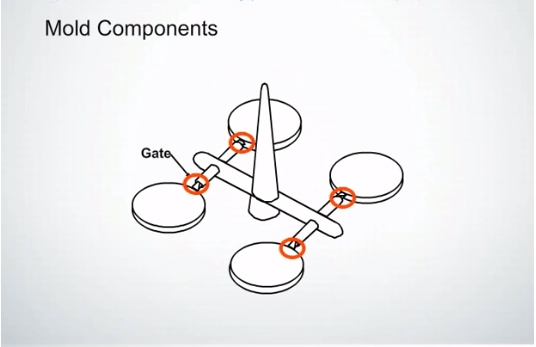

Gate referring to the plastic into the mold cavity molds.Types of Gates including; Edge, fans, perfect cashew and XME exclusive sites for free edge shear

Vestige material or material witness door runners have been removed and injected into the mold. The site usually trims molding machine operators.

Shear as the plastic into the mold and melt are generated by the friction velocity and pressure. Too much cutting can cause plastic burning, too little material to freeze led to a short ball

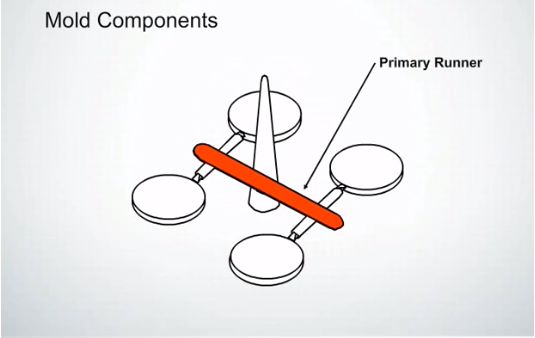

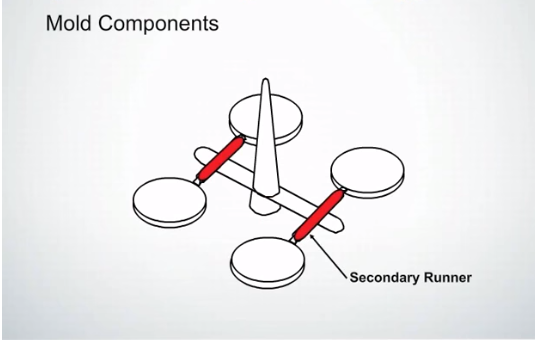

runner (hot runner) is used in the injection mold, plastic will melt into the mold cavity of the heating components in the set.

(1)

(2)

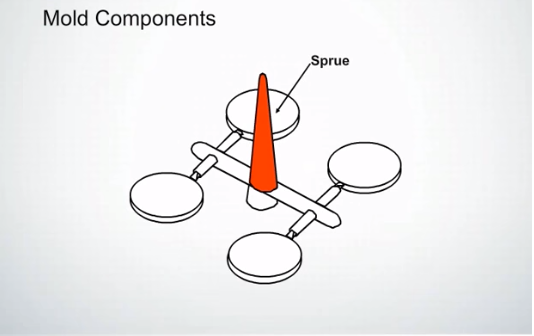

Sprue Perpendicular to the runner and sprue injection molding machine nozzle channel connected to the runner.

Cooling plastic products, to prevent product microcosm, Help plastics molding, Achieve a more beautiful effect

Hand Pull Custom injection mold parts in plastic parts are used to create weakened.

Slider The slider part of the custom plastic injection molds to create weakened.Need automatic injection mould.

Gibbs part of custom injection molds, so the cam can start sliding down.

CAM/HORN PIN Commonly referred to as the angle of cam/pin cam pin used to run a slide show automatically mould.

Ejector pins are used to promote a core part of the mold halves.

Undercuts Refers Weakened part of design components, you need to create a slider or hand holes, window or region does not draw a line.

The core tool for plastic parts will stick out, also known as the bottom half of the tool.

Cavities usually refer to the upper part of the injection mold showed the finished surface, but is concave. Not so much core outside of the tool. Parts usually does not persist when the injection molding machine mold is opened.

Core out of the part referring to the partially burned in order to achieve uniform wall thickness. This part other than the part did not end-use function reduce and reduce distortion.

Lines draw a line in the direction of two custom will be independent of the injection mould for plastic parts allowing it to be deported without any obstacle created from metal weakened.

Sider Action Is the term used for sliders and/or hand for injection mold building process. If your design requires action need a slide or hand made plastic parts molding process in order to run.

Part price refers to each plastic part in the molding production process.

SLA Stereo-Lithography equipment. Use 3-d printing techniques, such as laser and electron beam melting, “rapid prototyping” into “rapid prototyping,” actually completed prototype component in the short term.

FDM in fused deposition modeling. Prototype using three-dimensional printing technology is composed of fused actual ABS plastic. Just like ink-jet printers apart from its plastic instead of ink

Operators alone used to run a plastics injection molding machine. Mold may be a hand tool or product that can be stacked so that they do not fall on the other side when ejected from the injection molding machine.

wall thickness How the wall thickness of the thick section refers to the plastic parts.

Thin wall molding thickness of thin-wall injection molding plastic parts. 005. 060 thick.

A boss that means round bumps in the plastic parts and mould.

Ribe refers to the function of the thin blade used for strengthening the rib wall part and the boss. In addition, to reduce the deformation.

Sink Mark refers to the area that seemed to sink, because of the UN – uniformed wall part, the thick wall part thickness ratio and rib/boss.

Warp refers to the injection part area, the distortion or molding cooling, lead to undesirable results. Usually by my wall parts. prevention.

The draft angle refers to the parts of injection molded parts that have some form of taper. A draft general all plastic components should be designed. See the Design Guide recommendations.

The heel is a partially automated custom plastic injection molds, sliding at the forward position molding machine mold closes. vision.

Stock Safe refers to the metal in the mould of a number of shares in order to adjust the size. For example, if you have an inner diameter should be.500 you may leave the mold.505 if you shrink. It’s cheaper metal removal than it is to add it

Bulk Pack Is shipping in bulk plastic parts that do not have any form of superimposed on a box. In the injection molding machine, parts will be dumped in a box and shipped.

Reverse engineering refers to the existing plastic part process and creates a 3-d model of the injection molding process of copying. Sometimes from OEM designs may include some custom changes.