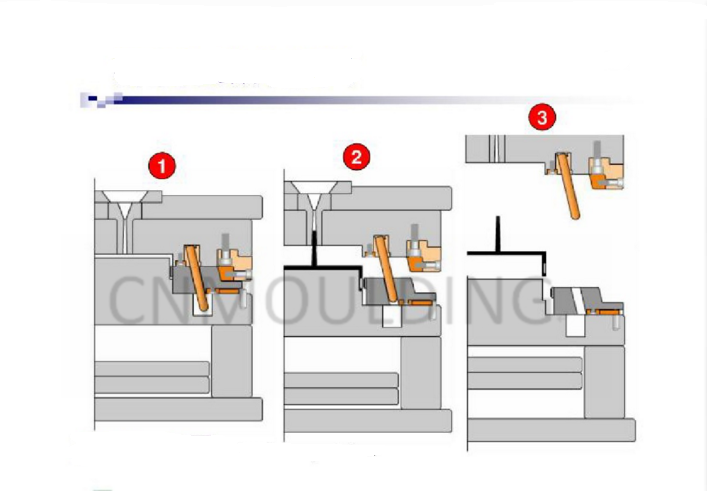

The slider

The slider is to solve the undercut (under-cut) and the development of the mold mechanism. The basic principle is to open and close the mold vertical movement, steering horizontal movement. And in order to cooperate with the male or female model barb position, and change the different forms of institutions. First to complete the lateral type, then top the product

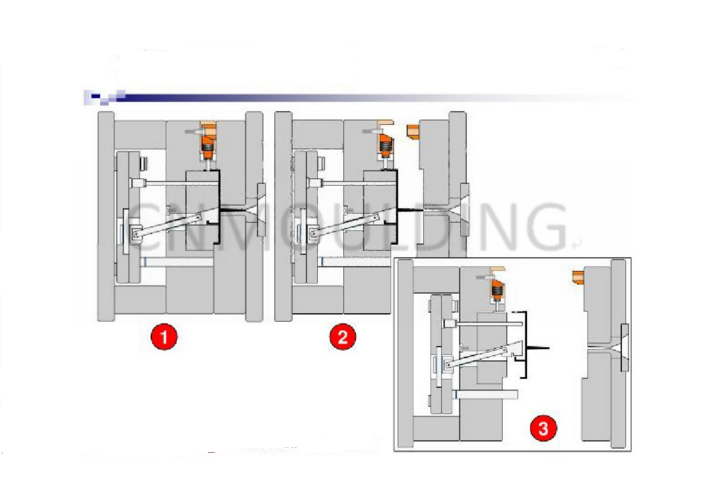

The angle pin

Angle pin Is the mold design used to shape the barbs inside the product body, suitable for a relatively simple barb case.

Angle pin is to solve the undercut (under-cut) and the development of the mold mechanism. The basic principle is the same mold opening, and closing of the vertical movement, steering horizontal movement. The biggest difference between the angle pin and the slider is that the driving force of the action comes from the action of the thimble board. Not the action of opening and closing the male and female templates like a slider. Since the angle pin must utilize the thimble plate driving action. The design of the sloping top is related to the stroke of the thimble. Which is also the biggest difference between the sloping roof design and the slider design.

Generally in the angle pin and the slider can be done under the condition of the main selection slider. Slider processing is easier to control, and in the mold and its interference components are much less inclined. Such as the angle pin will interfere with the support Column, thimble, when the top of the ramp and the top of the ramp, with thimble and another top of the mechanism of interference .. Slope also affect the larger waterway, etc. In the assembly and removal of the slider is relatively convenient. The top is basically one of the mechanisms used when a slider is unavailable

The slider is a mold assembly capable of sliding perpendicular to the mold opening. And closing direction or at an angle to the mold opening and closing mold opening operation. When the product structure makes the mold without the use of the slider can not be normal demoulding the use of the slider. The material itself has the appropriate hardness, wear resistance. Enough to withstand the friction of exercise. The cavity on the slider or core part of the hardness of the mold cavity with the core of other parts of the same level.