Injection mold cost

I feel that many companies who are doing injection mold tooling overseas for the first time do not understand the total cost of sourcing molds from China. They see the very competitive price and delivery but do not see the entire picture.

If they need to send a plastic injection mold tooling engineer over there at any point

How much does that cost?

If the plastic injection mold is going to be run in the U.S. then it will need to be shipped after the first article parts are approved. How much does it cost to delay full production while the plastic injection mold is in transit?

Many part designs have minor or even major issues in regard to whether they can be molded successfully when they are sent out for quotation. Is the draft done correctly? Can surfaces be shut off so as to ensure a reasonable plastic injection mold life?? Many times it is difficult to resolve these sorts of things. when dealing with an off-shore injection mold supplier. There are many U.S. mold makers who make a very good living re-working off-shore injection molds to deal with design issues that were not resolved in the beginning. That cost is seldom considered in the initial analysis of where to source a plastic injection mold tooling program.

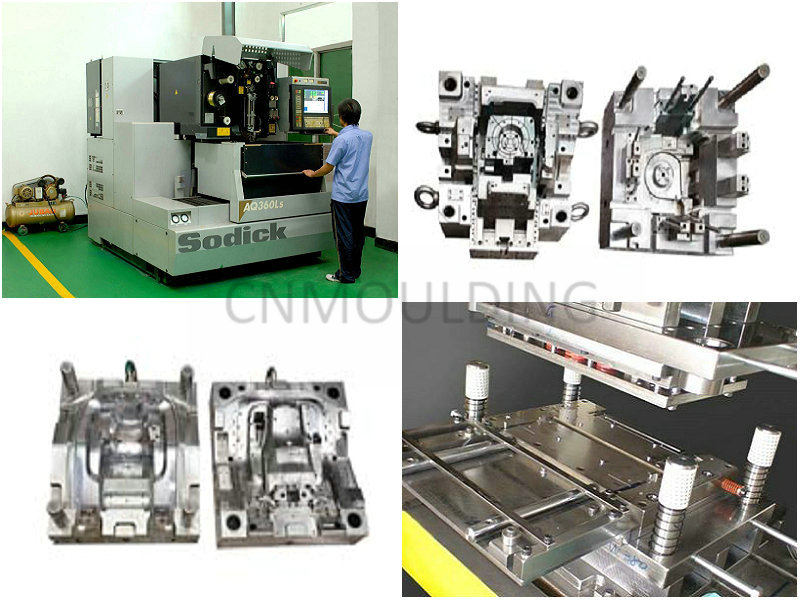

In all fairness, I have seen some very good plastic injection mold tooling come out of China. Sound mold making practices know no boundaries. A good domestic injection mold tooling broker can solve some of the concerns I have mentioned. But mine is by no means a complete list of issues or concerns that I have seen over the years.

Something also needs to consider is your product liability exposure. Will your current insurance carrier include that liability for the plastic injection molds from China? Some carriers are concerned with the fact that you aren’t making the plastic mold yourself. So how do they ensure for an exposure that they don’t know about? Also, you want to make sure you have an Ocean Cargo policy for the shipping. Normally once the product leaves the overseas company your insurance should pick it up. In other words, if something happens to the shipment while coming to you.

Many companies I deal with see a plastic injection mold tooling quote and never add in the”extras”. And here is my list of concerns buyers have mentioned.

What is the real landed price in my factory?

Understanding that the PO is for good parts/tools to run to EAU for X years not just samples.

Who covers all the freight costs for samples sent from China.

Are components used in injection mold tooling available in the US?

Does the PO for tooling include all CAD files required to make domestic plastic injection mold changes?

Our CAD files updated to reflect the actual injection mold tooling being shipped?

Was the plastic mold tooling sampled in an equivalent machine to the one it will run in in the US? Did the plastic injection mold run for 24 hours or just long enough to get enough samples.

Did you receive parts on the runner and not groomed, that will tell you a lot about what injection mold is being shipped to you.

There are so many concerns when buying a plastic injection mold for anywhere, but especially a country that takes 20 hours to fly to and has a work schedule that is 12 ahead of you.

Find plastic injection mold manufacturers in China

Besides the language, the cultural difference could be even more difficult in finding a Chinese plastic injection mold manufacturer. One example for cultural differences can be: if somebody asks for a certain quality of injection mold part or steel, and say at the end of the sentence “or similar quality”, this gives the cultural opening to almost do whatever as long as it seems to be similar in one or another way.

One of the big issues here is the design of the plastic mold and technical solutions. Also, the fact that injection molds from China to Europe and other places need to be 100% finished before shipment, otherwise, the cost with adjustment and reworking can be higher than the cheap injection mold price from a Chinese mold maker or trader. I have met so many plastic injection mold manufacturers in South and East China.

The problems are the following:

In China, the workers want to earn the money and the owner want also earn the money in a short time. So you could not easy to find some good workers, who could do the job for many years. If the owner finds out they could not earn so much money, they could invest in another area.

There is really a different culture between China and the West. If you find in another country, you will find such differences in India, which make also injection mold business, and South Korea. I think the reason is, how long the injection mold industry could be developing in the country. If the total mold industry would be developed so well, you will find that actually there are no so many differences. About the price. Why the customer in the EU and USA buy injection molds in China or India, South Korea. Only because of the price. Most of them do not calculate what behind such a low price.

If you only want to buy such a mold at a low price, you must accept the quality. Just like you in the EU and the USA. Some companies could also make very good plastic injection molds, but the price for some companies from the EU and the USA could not accept them. And the owner would also like to get a big order.