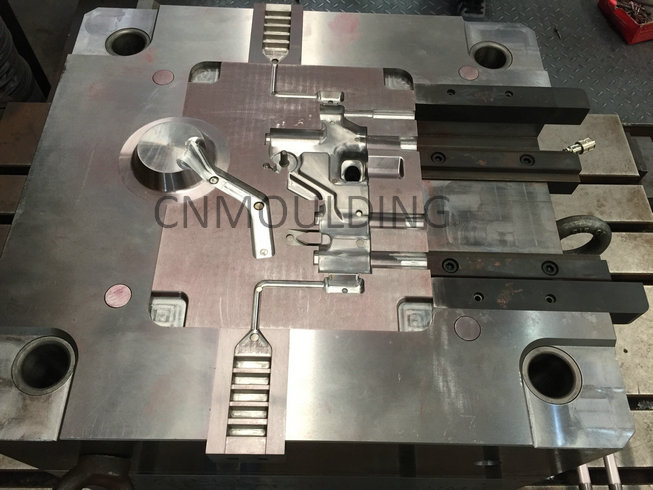

Die casting is a manufacturing process for producing metal parts by forcing molten metal under high pressure

into a Die cavity. Generally speaking, these Die or mold cavities are created with hardened tool steel that has

been previously machined to the net shape or near-net shape of the Die cast parts. This process allows

products to be made with a high degree of accuracy and repeatability. The Die casting process also produces

fine details such as textured surfaces or names without requiring further processing.

The ability to produce highly detailed and high accuracy parts make Die casting a suitable choice for the mass-produced product. The moment you wake up you are surrounded by-products that are produced by the Die

casting process. When you turn the faucet, you open the doorknob, when you drive your car, almost

every product or part of the product you use in your daily life is produced using this process.

The die casting process usually produces parts using primarily non-ferrous metals, such as zinc, copper, aluminum, and magnesium. Over the years, many different alloys have been developed to meet a certain type of needs and requirements

of each application.

Type of Die casting processes

The Die casting process can be further divided into two different categories:

1, Hot Chamber Die Casting

2, Cold Chamber Die Casting

Hot Chamber Die Casting is the process where the injection system is immersed in a pool of molten metal hence the name. The furnace is attached to the machine via a feeding system called a gooseneck. As the cycle begins the piston will retract, which allows the molten metal to fill the “gooseneck” from a port in the injection cylinder. As the plunger moves downwards, it seals the port and forces the molten metal through the gooseneck and nozzle into the Die. Once the metal solidifies, the plunger will pull upwards. Afterward, the Die will open and the part is ejected. The advantage of this process it’s short cycle time as it does not require metal to be transported from a separate furnace. Unfortunately, this Die casting process is only suitable for alloys that do not attack the injection cylinder such as zinc, magnesium, and copper.

Cold Chamber Die Casting is the process of using a ladle to transport the molten metal from the holding furnace into the unheated shot chamber or injection cylinder. This metal is then shot into the Die by using a hydraulic piston. The main disadvantage of this process is that it is relatively slower compared to the Hot Chamber Die Casting Process. However,

this process is primarily used for manufacturing aluminum parts as molten aluminum alloys have a tendency to attack and erode the metal cylinders, plungers and Die greatly shortening their tool life.

History

The Die casting process dates back to the mid-1800s when a patent was awarded to Sturges in 1849 for the

first manually operated machine for casting printing type. However, it was not until 20 years later that this

process has been used to produce other consumer products such as phonographs and cash registers.

In the beginnings, tin and lead are the primary alloys used for the die casting process, but these alloys

have been replaced by zinc and aluminum since the 1920s.

As technology advances, the die casting process has become more and more efficient. New technologies allow greater pressure in the injection process, thus allowing us to produce parts that are closer to net shape and higher integrity than

ever before.

Advantages of Die Casting Parts

One of the main advantages of Die casting is the ability to produce parts and products with a wide range of

shapes and sizes. Unlike other manufacturing processes such as extrusion, the Die casting process does

not limit the shape of parts and in most cases will be the net shape of the parts.

Durability:

Unlike plastic parts, Die-cast parts are stronger than their plastic counterparts. In most cases, this allows

parts to be produced with thinner walls while maintaining the strength that is required for its application.

Furthermore, Die cast parts are able to withstand a broader range of temperature, making it more ideal

in harsh temperatures and working environments.

Mass production at high speed:

Since the Die casting process can allow manufacturers to produce complex parts to net shape, there are little or no machining processes required thus reducing the production time making Die casting one of the most effective processes to mass-produce non-ferrous metal complex parts.

Green Manufacturing:

How long does it take for plastic to biodegrade? According to scientists, plastics take at least a few hundreds of years to degrade fully. This means that obsolete plastic products are pilled up in landfills, polluting our beaches, killing millions of sea animals and causing health hazards to the inhabitants in our neighborhoods. Unlike plastic, Die casting parts are primarily made of recycled material. On average, approximately 95% of the metal is recycled from salvaged parts making it a sustainable material that can be used over and over again without degradation.

Thinner Wall Castings:

Compared with sand and permanent mold castings, the Die casting process is able to produce parts with thinner walls due to the high pressure during the injection process. This allows lightweight construction as well as eliminates or reduces the need for secondary operations.

Casting with inserts:

The Die casting process allows inserts to be cast-in to form certain features such as threaded inserts, heating elements or high strength bearing surfaces.