China Injection Mold Cooling System

Injection molding is a widely used manufacturing process in which molten materials are injected into a mold cavity to create various products. The cooling system is a crucial element of the injection molding process, as it helps to regulate the temperature of the mold and ensure the quality and consistency of the final product. In China, injection mold cooling systems are widely used in various industries, from automotive to medical devices.

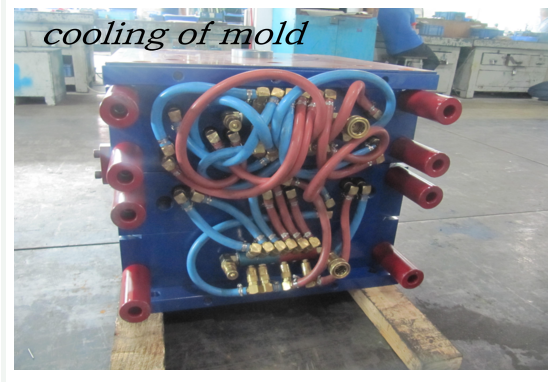

The injection mold cooling system consists of a series of channels or passages that are integrated into the mold. These channels allow for the circulation of a cooling medium, typically water or oil, which helps to dissipate heat from the mold. The cooling medium is circulated through the channels by a pump, which is typically controlled by a temperature controller. This allows for precise control over the temperature of the mold, which is critical for ensuring consistent quality and reducing cycle times.

There are several different types of injection mold cooling systems available in China, including direct cooling, indirect cooling, and hot runner cooling systems. Direct cooling systems are the most commonly used and involve the circulation of water or oil directly through the mold channels. Indirect cooling systems, on the other hand, use a heat exchanger to transfer heat from the mold to the cooling medium. Hot runner cooling systems are used in situations where the mold requires precise temperature control, such as in the production of medical devices.

One of the key advantages of injection mold cooling systems is their ability to reduce cycle times. By regulating the temperature of the mold, these systems can help to speed up the cooling process and reduce the time it takes to produce each part. This can be particularly beneficial in high-volume production environments where speed and efficiency are critical.

Another advantage of injection mold cooling systems is their ability to improve product quality. By regulating the temperature of the mold, these systems can help to prevent defects such as warping, sink marks, and surface blemishes. This can help to ensure that each part produced is of consistent quality and meets the required specifications.

In conclusion, injection mold cooling systems are an essential element of the injection molding process in China. With their ability to regulate temperature, reduce cycle times, and improve product quality, these systems are widely used across various industries. As technology continues to advance, we can expect to see even more sophisticated injection mold cooling systems being developed in China and around the world.